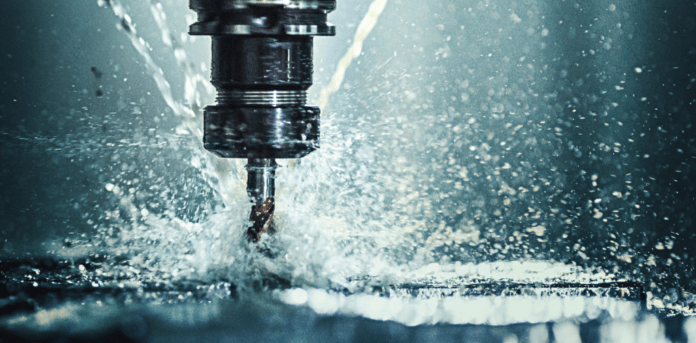

The benefits of CNC machining are many. These machines are extremely accurate, resulting in a very uniform end product. This is a major benefit in a variety of industries. These companies must produce highly precise parts with a high degree of uniformity, or their final products will not work properly. They can also replicate virtually any object, from simple to complex, without any human intervention.

This process is ideal for manufacturing demanding applications

It allows you to produce incredibly small parts with unique features, while still maintaining high-level precision. In addition, this process can allow you to make multiple parts with similar dimensions and features without any problem. If you’re looking for high-quality, repeatable parts, CNC is the right choice. If you’re not sure if CNC is the right fit for your business, check out the benefits of this process.

Multiple prototypes can be produced simultaneously

Compared to other manufacturing methods, CNC machining is a fast, easy, and accurate process. In most cases, you can complete hundreds of units in a short period of time. In comparison, 3D printing and injection molding require a large amount of setup and maintenance. However, with CNC machining, you can easily produce multiple, usable prototypes at a time.

Not cheap but not wildly expensive

Using this process is not cheap. It’s not cheap, but it’s not wildly expensive, making it the ideal choice for production projects where quality is a higher priority than cost. In contrast, other processes such as 3D printing and injection molding are inexpensive and can be used for low-volume production. So, which one should you use?

Safer operation

Besides being fast, CNC machining has a wide range of other advantages as well. It’s safer: Unlike manual machinists, CNC operators are at a safe distance from sharp tools. This means you’ll have a safer, happier workplace. This is one of the reasons why you should choose CNC machining. If you’re thinking about pursuing this process, it’s important to take some time to decide how it fits your production needs.

CNC machining allows for complex shapes and textures

It’s also faster than traditional methods, and it’s more accurate. It eliminates human error, allowing you to create better-quality prototypes faster. A CNC machine can also produce multiple usable units within the same timeframe, which means that the cost is lower. That’s a big plus for any company. There are many other benefits of CNC machining as well.

You can make changes to the design

Another benefit of CNC machining is that it allows you to make changes to the design. Using a CNC machine, you can create many different designs simultaneously and can create countless identical components in a matter of minutes. Further, it allows you to add holes to your products. You can use it to make prototypes for your company, as well as to create prototypes for sale. You’ll be able to test out different parts and test them in the market.

Conclusion:

CNC machining is a more efficient and accurate way to manufacture products. Because it can reduce human error, you’ll be able to produce parts that are consistent and accurate. This is a big plus for any manufacturer, and it is why it is the preferred method of a large number of companies. You won’t have to worry about the safety of your employees, and you can hire experienced staff.